"Please bear with us as we face order delays and product shortages.” This has become the official response of vendors and manufacturers for the past two years. And it’s not any individual company’s fault. Thinking back on how things were, we were lulled into expecting smooth and reliable procurement as a given, whether picking a product off the shelf as a consumer or ordering your business products. Now, there seems to be a continuum of reasons as to why the products are not either readily available or why you have to wait in a queue to get them.

The truth is, the current stressed state of the global IT supply chain should not have been a surprise. There are many factors, some of them related specifically to the technology ecosystem and others based on broader economic and political issues. The pandemic is certainly the catalyst brought about by the sudden volatility in demand. At the beginning of the pandemic, there were demands for personal computers as people migrated to work at home. Some employees hauled their desktop computers home but most transitioned quickly to notebook form factors. In addition, schools implemented remote learning and needed to get low-cost Chromebooks into the hands of students attending classes at home via collaboration software. Outside the technology industry, the automotive world’s need for semiconductors became painfully obvious. This will be the subject of a follow-on note.

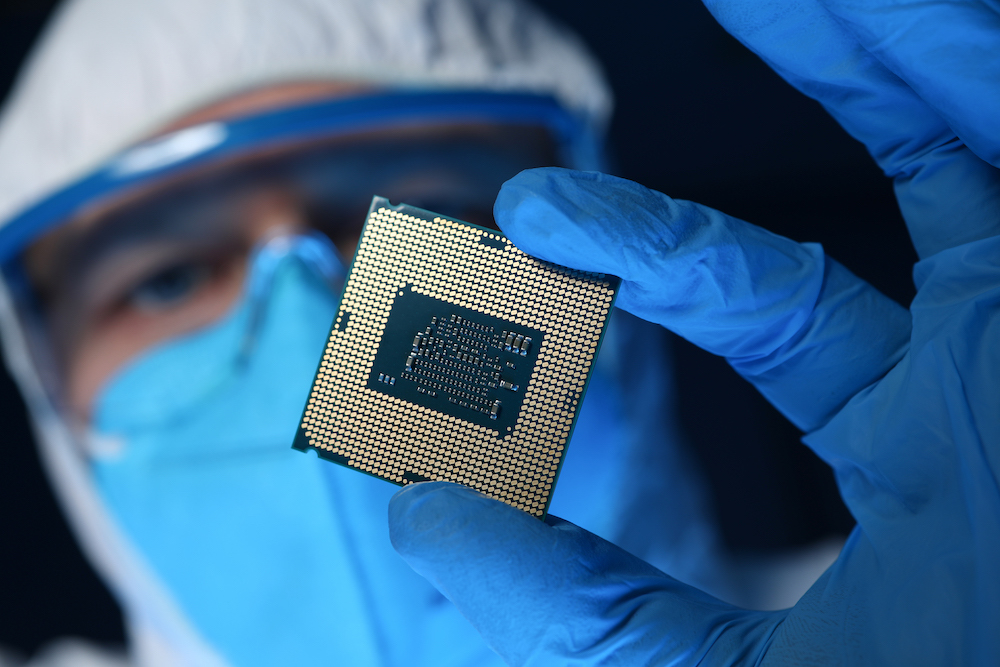

Technology vendors are still called OEM or Original Equipment Manufacturers, a quaint term that no longer represents the current manufacturing reality. By and large, technology manufacturers have moved to an outsourced model. Initially, they contracted the final assembly of componentry into the technology products we use today whether it is PCs, networks, servers, and other hardware. Over the years, the assemblers took on an increasing amount of design work and are now called Original Design Manufacturers or ODMs. These companies take the design requirements specified by technology vendors and build the products themselves.

The level of involvement by OEMs in the design and manufacturing is quite different for each vendor. On one end of the spectrum is Apple who is very involved in the design phase, going so far as to architect their own microprocessors such as the M1 processor found in the newest Macs. Other OEMs use standard components available from a catalogue of semiconductors designed by highly specialized vendors.

In the end, the industry has created technology combining high quality, high volume, and competitive pricing, and has produced a very powerful impact on business and society. In the next note, I will be highlighting why the model we have created will be very challenged over the next few years and presents risks both in cost and availability that every business will need to plan for.

.png)